There are many considerations when attempting to make high-quality baleage. One aspect is bale density. Recent research at Penn State University helps producers understand the importance of making dense bales.1 This study evaluated balers set to bale at maximum density traveling at three different speeds: 4, 8, and 12 mph (3.2, 4.8 and 6.4 km/h). Bales were wrapped within 4 hours after baling at a minimum of 6 mil of wrap on each bale to exclude oxygen and control heating.

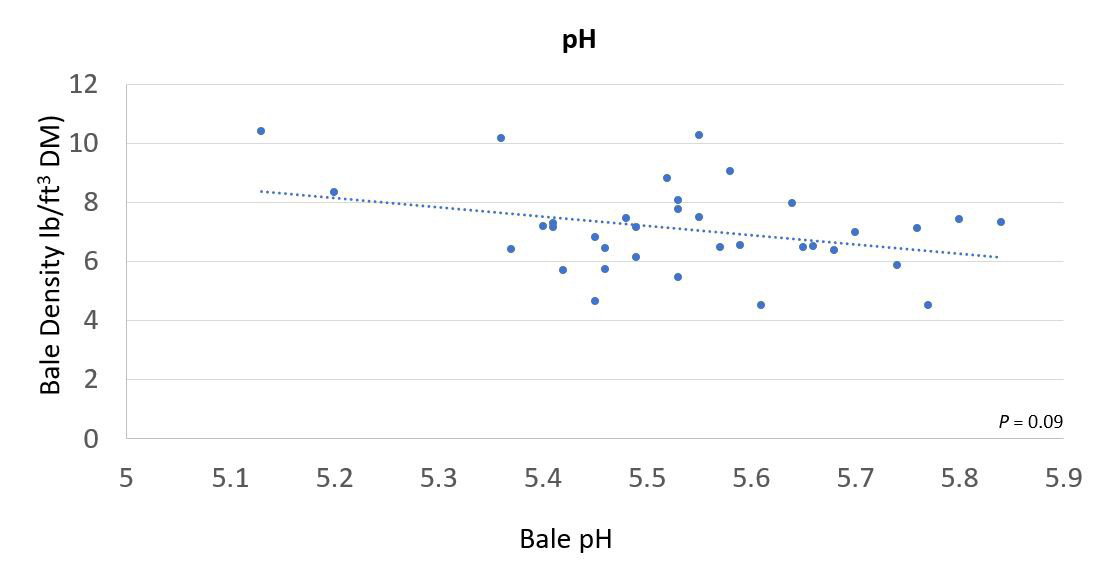

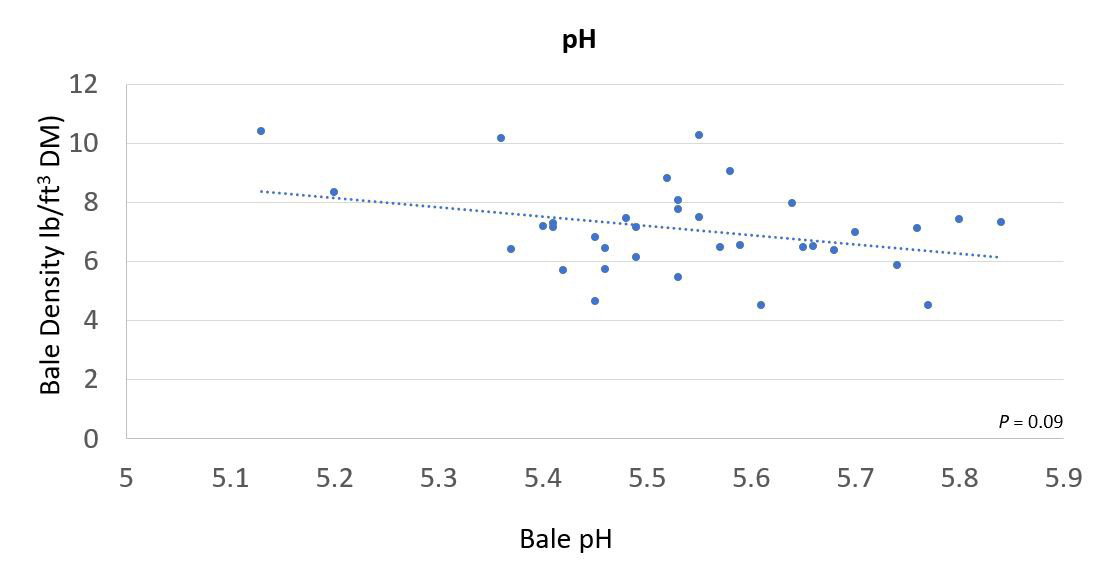

After 28-days of storage, the research team found bale density directly impacts baleage quality. Across all speeds, the greater the bale density, the lower the pH of the bales (Table 1). This indicates proper fermentation of the sugars available under anaerobic conditions. As forages ferment, anaerobic bacteria convert sugars to acids during the fermentation process. A low pH is desired to help increase storage time, reduce mold and wild yeast growth and to reducing forage heating during feed out.

Figure 1. Baleage pH decreases as bale density increases.

An additional challenge for producers trying to make high-quality baleage occurs when fermentation is slower than other silage. There is less sugar available for growth of lactic acid producing bacteria in baleage resulting in a longer period of fermentation. During this extended fermentation, mold and wild yeast growth reduces the quality and quantity of the forage.

A research team at Kemin Industries,2 completed an evaluation using Silage SAVOR® Plus Liquid Silage Preservative on baleage of approximately 40% moisture (60% dry matter). Silage SAVOR is a blend of organic acids, formulated specifically to reduce mold and yeast growth in ensiled crops. Treated bales received an application of 500 grams of the organic acid blend per ton of hay (approximately 830 grams per ton of dry matter). After a 40-day fermentation period, each bale was weighed, and dry matter retention was calculated. Core samples were taken from each bale, and samples were sent to a laboratory for analysis of fermentation properties including pH, lactic acid, acetic acid, propionic acid, ammonia-N and total acids.

Dry matter retention is one measure of how well bales were preserved. Dry matter retention was better for the treated baleage when compared with the untreated bales (Table 1).

Table 1. Dry matter of alfalfa baleage before and after 40 days of ensiling.

Parameter

|

Untreated

|

Treated*

|

Initial Dry Matter, %

|

57.7

|

57.4

|

Final Dry Matter, %

|

56.0

|

56.9

|

Dry Matter Retention, %

|

97.1

|

99.1

|

* Treated with 500 grams of Silage SAVOR Plus Liquid per ton of as-is hay.

Not only was dry matter retention enhanced with an application of Silage SAVOR, but other fermentation parameters improved (Table 2). By controlling the growth of non-beneficial mold and wild yeast, the application of the blended organic acid reduced competition for lactic acid-producing bacteria resulting in a more complete fermentation.

Table 2. Fermentation properties of alfalfa baleage after 40 days of ensiling.

Parameter

|

Untreated

|

Treated*

|

pH

|

5.45

|

5.43

|

Ammonia-N, % CP

|

3.13

|

2.82

|

Lactic acid, %

|

0.41

|

0.56

|

Acetic acid, %

|

0.09

|

0.22

|

Total Acids, %

|

0.49

|

0.78

|

* Treated with 500 grams of Silage SAVOR Plus Liquid per ton of as-is hay.

The use of Silage SAVOR improved the fermentation characteristics of alfalfa baleage. Silage SAVOR improved lactic acid and total acid levels over the untreated baleage. Therefore, the use of Silage SAVOR should provide a forage producer with superior fermentation of alfalfa baleage.

Along with maximizing density and using Silage SAVOR, there are several other considerations when making high-quality baleage. University and extension resources offering suggestions for making high-quality baleage are readily available. As an example, Michigan State University offers management guidelines for producing high-quality bale silage3 include:

- Wrap at 50-60 percent moisture.

- Only mow and harvest a crop area that can be handled in the time it will dry from about 50 - 60 percent moisture.

- Number and date each bale and store the bales by field and cutting.

- Keep forage species and soil fertility consistent across fields.

- When balancing rations, strive for a representative, composite forage sample.

- Try to incorporate other forages in the ration so that baleage is not the only forage fed.

High-quality baleage is an excellent addition to any cattle ration. However, making high-quality baleage requires the same attention to detail required for any forage. By addressing each of these steps, you can make better baleage this year, and every year.

References

1Hall M., and J. Williamson, “Bale Density Effects on Baleage Quality” Penn State Extension, May 2019, https://extension.psu.edu/bale-density-effects-on-baleage-quality Accessed March 16, 2020.

2Hermesmeyer G., and V. Sewalt, “Efficacy of Organic Acid-Based Forage Preservatives in Enhancing the Fermentation Properties of Alfalfa Baleage,” WP-02-00841.

3Harrigan, Tim, “Harvesting and Handling High-Quality Baleage”, Michigan State University Extension, June 2017. https://www.canr.msu.edu/news/harvesting_and_handling_high_quality_baleage. Accessed March 19, 2020.