Uniqueness of Formic Acid

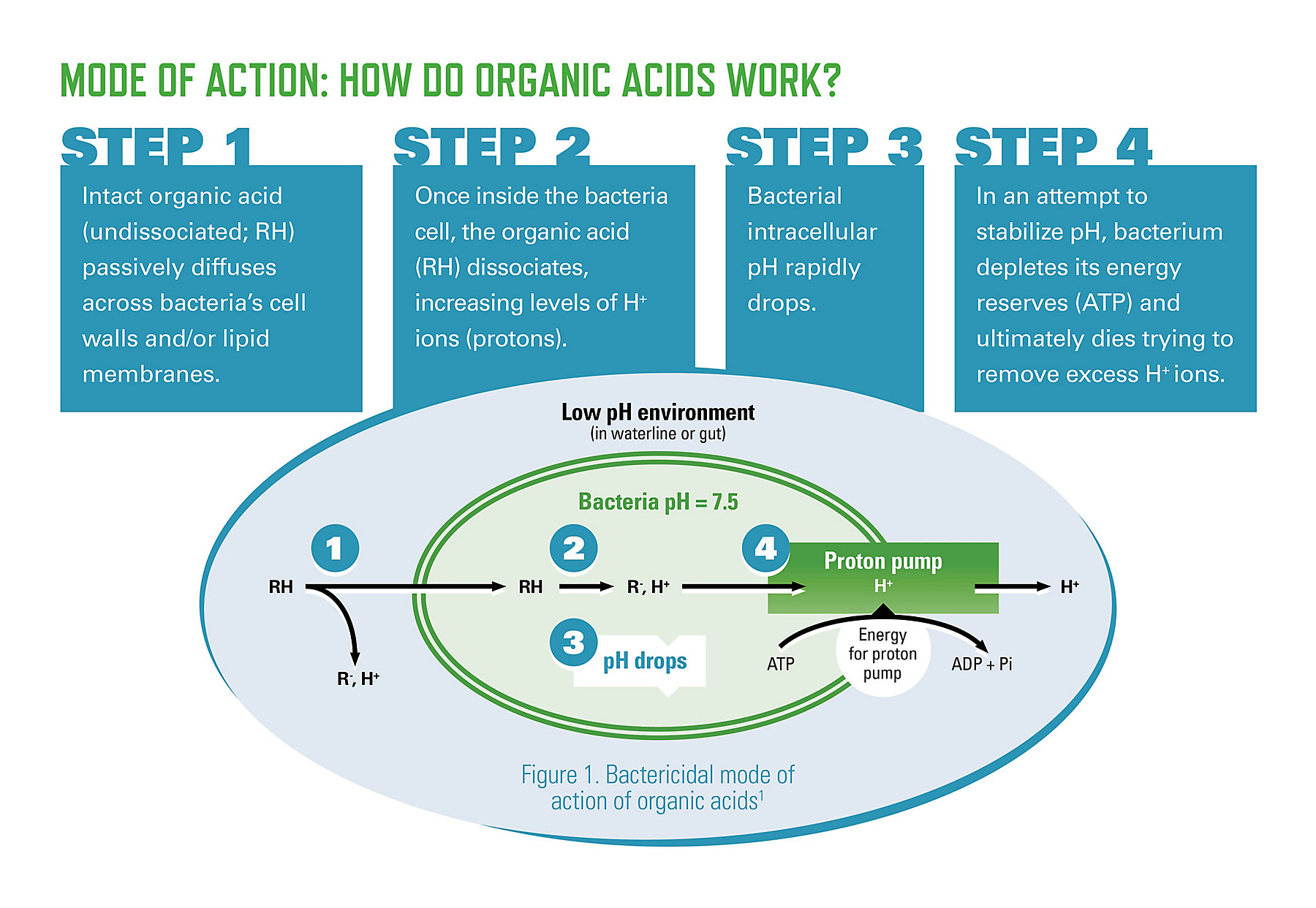

Each organic acid has unique properties and benefits based on its chemical structure. One of the major factors for the effectiveness of formic acid is its small molecular size and chain length (HCOoH), which allows it to enter the bacterial cell easily compared to other organic acids.

Formic acid is also unique in that it has one of the lowest pKa (acid dissociation constant, 3.75) of any organic acid. pKa is the pH at which half of the acid is dissociated. A lower pKa indicates that it's a relatively strong acid and would be able to donate its H+ ion easily. In other words, once inside the bacterial cell, the H+ ion becomes free easily, which will bring the pH down quickly, and the bacteria needs to spend its energy at its own detriment to export it out and maintain the pH.8

FORMYL™ Na

FORMYL Na is an encapsulated form of formic acid salt manufactured using a proprietary process which delivers the active molecule throughout the gastrointestinal tract. Multiple research and field trials conducted indicate that FORMYL Na was able to reduce the issues associated with disease-causing microbes in live birds, improve performance and decrease the bacterial load as birds go to processing. FORMYL Na, by utilizing the unique nature of formic acid and proprietary encapsulation technology, provides value to producers by improving bird health and decreasing the thread of foodborne illnesses.9-11

To learn more, visit www.kemin.com/formylna.

References

1Thøfner, Ida and Christensen, Jens-Peter, 8 - Bacterial diseases in poultry, in Advancements and Technologies in Pig and Poultry Bacterial Disease Control, N. Foster, I. Kyriazakis, and P. Barrow, Editors. 2021, Academic Press. p. 199-227.

2Amalaradjou, Mary Anne Roshni and Bhunia, Arun K., Chapter Five - Modern Approaches in Probiotics Research to Control Foodborne Pathogens, in Advances in Food and Nutrition Research, H. Jeyakumar, Editor. 2012, Academic Press. p. 185-239.

3Ahmed, S. T., Hwang, J. A., Hoon, J., Mun, H. S., and Yang, C. J., (2014). Comparison of single and blend acidifiers as alternative to antibiotics on growth performance, fecal microflora, and humoral immunity in weaned piglets. Asian-Australas J Anim Sci. 27: 93-100.

4Pearlin, B. V., Muthuvel, S., Govidasamy, P., Villavan, M., Alagawany, M., Ragab Farag, M., Dhama, K., and Gopi, M., (2020). Role of acidifiers in livestock nutrition and health: A review. J Anim Physiol Anim Nutr (Berl).

5Vassilis Papatsiros. V. G., C. Billinis, The Prophylactic Use of Acidifiers as Antibacterial Agents in Swine, in Antimicrobial Agents, D.V. Bobbarala, Editor. 2012, InTech.

6Jacela, J. Y., DeRouchey, J. M., and Tokach, M. D., (2009). Feed additives for swine: Fact sheets – acidifiers and antibiotics. Journal of Swine Health and Production. 17: 270-275.

7Mannina, Paolo, Mani, Venkatesh, Rubach, Jon, Camellini, Claudia, Arduini, Lauro, and Lao, Ye, (2018). Development of a New FORMYL Product for the US Poultry and Swine Market. Kemin 18-00030.

8Ricke, Steven C., Dittoe, Dana K., and Richardson, Kurt E., (2020). Formic Acid as an Antimicrobial for Poultry Production: A Review. Frontiers in Veterinary Science. 7.

9Mani, Venkatesh, Rubach, Jon, Mannina, Paolo, and Poss, Mitch, (2017). Evaluation of a Micro Encapsulated Formyl Na Treatment on Mitigation of Necrotic Enteritis And Improving Growth Performance In Broilers. Kemin 17-00227.

10Van Meter, Patty, Mani, Venkatesh, Rubach, Jon, Mannina, Paolo, and Poss, Mitch, (2019). Formyl™ Na Process Validation Testing. Kemin 19-354.

11Iseri, Vanessa, (2020). Evaluate FORMYL™ Na on broiler performance and Salmonella and Campylobacter prevalence at the processing plant. Kemin 20-6430.

12Lückstädt C, editor. Acidifiers in animal nutrition. Nottingham University Press; 2008.