Keys to Phytogenic Efficacy

Though there is a risk of resistance — albeit a low one compared to other microbial treatments — phytogenics are inherently lower in risk because their natural, plant-based composition contains different molecules with diverse structures. Unfortunately, no two plants are identical in nature, making it a challenge to yield a consistent final product. That’s why Kemin puts such a premium on specific steps in the plant breeding and production processes, so producers have a final product that provides consistent active ingredient levels for dependable microbial suppression. To date, Kemin phytogenic plants are produced using classical breeding methods.

“We identify plants that have the right balance of active molecules in them and essentially go through a breeding process that yields a high concentration of those active molecules,” said Tonda, who added that Kemin researchers have developed two patented oregano lines that yield consistent essential oil phytogenic products. “Our process yields consistency in quality and 60% active molecules in our essential oils. We propagate the same plant multiple times, then transplant them into the field. This ensures every single plant is consistent. For our geneticists, it’s about finding a plant that works and figuring out how it will grow.”

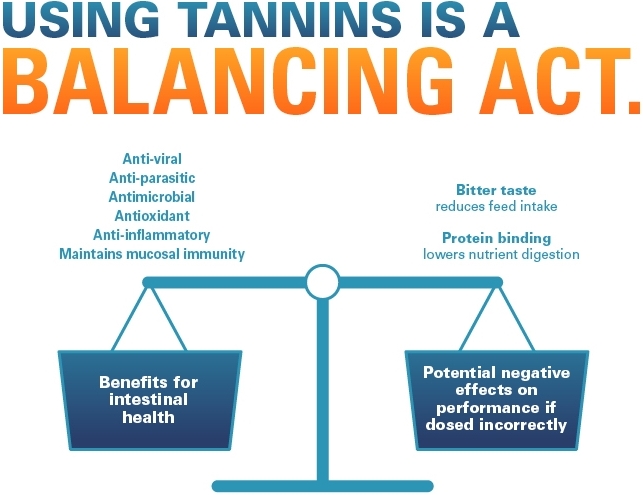

This kind of process is critical to the quality and long-term efficacy of any phytogenic. The active molecules must be administered in the right amounts to be effective. Though insufficient levels can lead to resistance and weakened pathogen damage control, higher concentrated levels can be just as harmful, especially when administered alongside another product, according to Brett Lumpkins, Director of Research and President of Southern Poultry Feed and Research in Athens, Georgia. Lumpkins leads research evaluations on phytogenics for the poultry industry.

“Concentrated oregano at high levels can be toxic. It would wipe out coccidiosis. If you’re using a coccidiosis vaccine in an antibiotic-free production system and have concentrations of oregano that are too high, you’re going to kill the oocysts in that vaccine and render it useless,” Lumpkins said. “We don’t want to create harm, destroy the vaccine or create a toxic environment.”

Coccidiosis is virtually omnipresent in poultry barns around the nation, though commonly at subclinical levels, meaning the parasite does not inflict damage to birds’ GI tract. It’s only when the parasite is able to flourish that it begins to destroy gut lining. In this specific case, a phytogenic administered at the right levels can help prevent coccidiosis from inflicting damage.

“It’s a matter of working together with facility managers in the field, keeping birds healthy and meeting their nutritional requirements,” Lumpkins said. “We don’t want nutrients floating around the GI tract of the bird — we want them all absorbed. Nutritionists and veterinarians can work together to supplement feed in a way that maximizes nutrient absorption and prevents damage from things like coccidiosis and necrotic enteritis.”

Phytogenics’ Future

This underscores the importance of quality control and consistency like that in Kemin phytogenic production, and points to the most effective use of phytogenics in current poultry production systems. Though researchers are working toward ways phytogenics alone can prevent damage in the presence of a pathogen infection, work still remains before that becomes a reality for ABF poultry production. Until then, a combination of phytogenics and conventional vaccines remain an effective way to prevent damage in the presence of high pathogen levels.

“I don’t think there’s going to be a single silver bullet. A lot of these products work on mild disease pressures, but with a more intense disease threat, it’s a greater challenge, and that’s where antibiotics are used. Without the use of antibiotics, it’s difficult to reach the same level of protection,” Lumpkins said. “Right now, we can test phytogenics and compare them to antibiotics at subclinical levels, and nutritionists and veterinarians are working together to find the best solutions. Determining the right phytogenic levels to reach the same level of control is an attainable goal, and it’s what the consumer wants.”

Until that solution is reached, it will remain critical to understand the MOA of each phytogenic, Tonda said. Doing so can help producers develop strategies that can ultimately lead to phytogenics becoming the primary mechanism for controlling pathogen damage.

“The ABF movement has created a lot of challenges for managing intestinal health in poultry. Many companies have feed additives they’re trying to promote as alternatives to antibiotics, and there are a lot of products out there,” she said. “It’s important to work with a company that has the highest standards for product consistency and will educate you on how these products work, specifically with modes of action. There are a lot of positive aspects to phytogenics; we just have to balance those benefits by optimizing modes of action and doses. It starts by doing the research to understand how phytogenic products work.”