You are viewing United States

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

A global presence, with local expertise. Visit our regional sites:

- United States

- Canada

- Mexico

Popular Searches

- Animal Nutrition & Health

- Myco CURB®

Myco CURB®

Mold Inhibitor

Myco CURB® and Kemin are names recognized worldwide as the pioneer in feed preservation. Myco CURB, an organic acid combination for feed, helps preserve nutrient value and quality of feed by reducing mold contamination. Buffered for worker safety and to help prevent metal corrosion, Myco CURB is available in liquid and dry formulations.

Kemin is recognized in the feed industry for pioneering nutrient preservation of feed using blended organic acids for controlling mold growth. Over the years, Kemin tested, evaluated and perfected various combinations before arriving at the formulation for Myco CURB. Since launching Myco CURB, this non-corrosive mold inhibitor has changed how feed and feed ingredients are handled. By controlling spoilage organisms, Myco CURB gives producers of meat, milk and eggs a powerful management tool to increase production by wasting less feed and maintaining quality in their operations.

What is Myco CURB?

Myco CURB is a mold inhibitor for livestock feed, formulated to inhibit mold growth in processed feed ingredients, complete feed and total mixed rations (TMR). Myco CURB contains propionic acid blended with sorbic and benzoic acids and is buffered for improved equipment and employee safety.

Why is Myco CURB unique when compared with other acid preservation products?

Myco CURB is the industry leader in feed preservation because of its unique blend of ingredients. Kemin scientists developed this proprietary blend of organic acids and antioxidants to control mold growth in feed and feed ingredients. Over the years, producers and feed manufacturers have relied on the efficacy of Myco CURB Liquid to control mold growth in stored grain, increase the shelf-life of bagged feed and protect animal and poultry production by controlling performance-robbing microorganisms. Applied using Kemin-engineered application systems, Myco CURB Liquid coats the feed and feed ingredients to deliver reliable protection against a range of mold species.

Myco CURB Dry was developed for feed manufacturers and livestock and poultry producers who choose not to handle liquid products. The technology used by Kemin to manufacture Myco CURB Dry results in a free-flowing, granular product with excellent mold control efficacy. Myco CURB Dry is applied in base mixes and premixes, through micro bins, or as a hand-added ingredient. The granulation process reduces dust, thus, reducing worker exposure to fine particles.

What else should I consider when choosing a mold inhibitor?

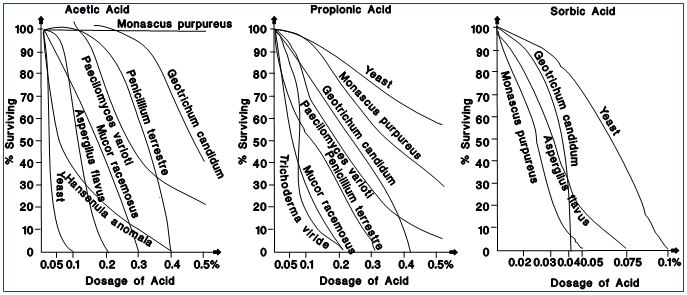

When choosing a mold inhibitor, it is important to know that each individual organic acid will have a different effect in controlling molds. The data in Figure 1 indicates a mold inhibitor combination, involving more than one organic acid, is best suited within a feed mill.

Figure 1. Effect of various organic acids on mold growth

Another consideration when evaluating a mold inhibitor is the surfactant. Surfactants are used to lower the surface tension of liquids. When used in acid blends, surfactants help acids penetrate grain surfaces. Flaking operations use surfactant technology in grain preservation to enhance steam penetration.

Is Myco CURB available as a liquid or dry formulation?

Kemin sells Myco CURB in both liquid and dry formulations.

- Myco CURB® Liquid is a blend of organic acids formulated to inhibit mold growth in processed feed ingredients, complete feed and TMR. It contains 65 percent propionic acid blended with sorbic and benzoic acids. This blend of acids inhibits the typical mold growth found in grains or processed grains during storage, handling and export shipments

- Myco CURB® Dry is also a blend of three powerful organic acids. After completion of a reaction to form an acid salt, this dry form is granulated to reduce dust and worker exposure. As with the liquid formulation, Myco CURB Dry contains antioxidants and surfactants to enhance the efficacy of the mold control

How does Myco CURB compare with other blended organic acid products?

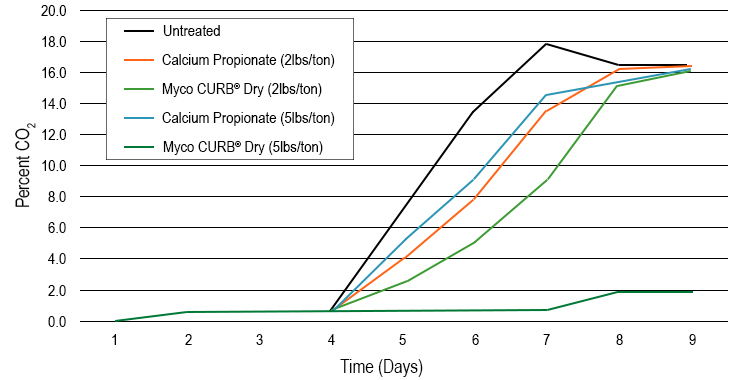

In Figure 2, a study comparing Myco CURB Dry mold inhibitor and calcium propionate in a finisher feed showed the ability to control microbial spoilage did not change with an increased application rate of calcium propionate. Whereas, increasing the application rate of Myco CURB Dry from 2 lbs/ton to 5 lbs/ton further improved its efficacy and significantly reduced mold growth in the finisher feed during the nine days of monitoring.

Figure 2. Efficacy of treatment on CO2 production in a finisher feed

Will Myco CURB Liquid damage my metal equipment and is Myco CURB Liquid safe for my workers?

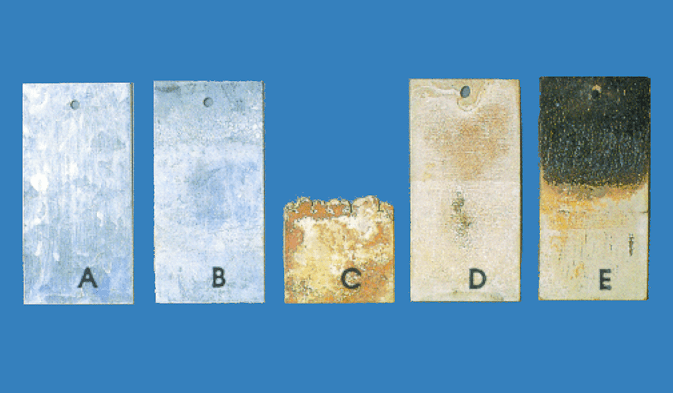

Mold inhibitors benefit the feed industry by increasing the relative microbial stability of feed and feed ingredients. In general, the active ingredients of these compounds are based on short-chain organic acids that are normally considered quite corrosive. The buffered acids in Myco CURB Dry and Myco CURB Liquid help protect equipment and employees.

An experiment was conducted to test the relative corrosiveness of three mold inhibitors on galvanized, low carbon steel. This material was selected because it is one of the most common construction materials in the feed industry.

AOriginal galvanized strip

B100 percent water

C80 percent propionic acid and 20 percent water

D80 percent Myco CURB Liquid and 20 percent water

E80 percent Mold Inhibitor A and 20 percent water

Figure 3. Results of 10 days of partial immersion of galvanized test strips in liquid mold inhibitors

As shown above, this experiment demonstrates Myco CURB is the least corrosive among the three liquid mold inhibitors tested.

Kemin pioneered the use of blended organic acids in the feed industry. For the past four decades, Kemin product development optimized the formulation of Myco CURB and the resulting formulation is still the industry standard for mold and wild yeast control. Research over this period of time has demonstrated that Myco CURB works to safely control microorganisms while enhancing the bottom line of feed manufacturers.

Product Specifications

Resources

References

1Pelhate, J. 1973. Ann. Technol. Agric. 22:647-661.

Have a Question?

If you have a question about our products or services, or just want more information, fill out the form below and someone on our team will be in contact with you.

Products

Careers

Careers

- California Residents

- California Supply Chain Act

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

© Kemin Industries, Inc. and its group of companies All rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements.

You are viewing United States

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

A global presence, with local expertise. Visit our regional sites:

- United States

- Canada

- Mexico

Privacy Policy

By browsing this site you permit us and our partners to place identification cookies on your browser and agree to our use of cookies for marketing. Review our cookies policy for details.

%20-%20English_04.pdf/_jcr_content/renditions/cq5dam.thumbnail.319.319.png)

%20-%20English_07.pdf/_jcr_content/renditions/cq5dam.thumbnail.319.319.png)