You are viewing South Asia

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

- Global

Choose Your Location:

- United States

- Canada

- Mexico

Popular Searches

- Animal Nutrition & Health

- Kem LAC® HD

Kem LAC® HD

Kem LAC® HD - Water-Soluble Silage Inoculant

Kem LAC® HD is a water-soluble silage inoculant containing a mixture of three lactic acid-producing organisms, which improve fermentation of silage. Kem LAC HD is used on a wide variety of forages chopped for ensiling. This high-density formula provides more beneficial silage bacteria per gram than other products available on the market.

Which bacterial strains are used in Kem LAC HD?

Kem LAC HD contains a mixture of lactic acid-producing bacteria (LAB) to help speed fermentation.1 These bacterial strains are: Lactobacillus plantarum, Lactobacillus acidophilus and Lactobacillus bulgaricus. The high levels of lactic acid produced by this combination of bacteria helps to quickly lower pH and preserve the crop.

Which forage crops ferment faster with Kem LAC HD added?

Kem LAC HD works in a wide variety of forages including corn, wheat, sorghum and alfalfa silage. By speeding fermentation, this three-strain silage inoculant helps reduce dry matter loss and preserve nutrient availability.

By reducing dry matter loss, Kem LAC HD helps to optimize the nutritional quality and silage longevity of your crop by retaining more energy and protein. Kem LAC HD also controls silage temperatures in the silo, while helping to reduce silage loss or shirinkage.

What does research demonstrate about Kem LAC HD?

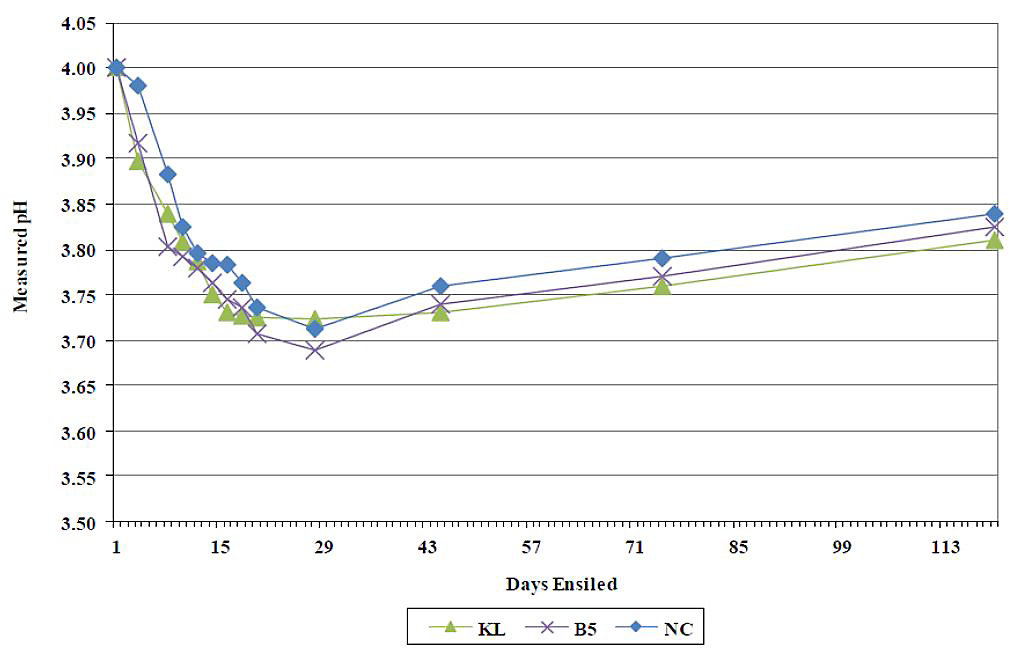

A trial conducted in 2012 evaluated the effectiveness of two water-soluble, bacterial silage inoculants, Kem LAC HD (KL) and an industry-leading silage inoculant (Product B5), for changing pH and promoting organic acid production in corn silage. Corn silage was treated with KL, B5 or water as a negative control (NC). The objective of this inoculant evaluation was to measure the effects of KL, which contains three LAB organisms, versus B5, which contains two varieties of Lactobacillus plantarum. The only acid production in the NC silage came from epiphytic (natural) bacteria found in untreated corn silage. Both Kem LAC HD and B5 promoted faster pH drop and more complete fermentation than the untreated silage. Both treatments produced greater (P < 0.05) amounts of lactic acid and significantly lower (P < 0.05) pH by 28 days post ensiling. Kem LAC HD-treated silage produced less (P < 0.05) ammonia than both the B5 and NC-treated silages by 28 days post ensiling. This suggests the Kem LAC HD-treated silage conserved more protein during the fermentation process. The pH of Kem LAC HD and B5-treated silages remained lower during the entire 120-day fermentation (Figure 1) and were significantly lower (P < 0.05) after 120 days of fermentation than the NC-treated silage.

Figure 1. Patterns for pH change in corn silage through 120 days in silos

Kem LAC HD rapidly drops pH. Does Kem LAC HD impact aerobic stability?

Varying degrees of aerobic deterioration occur before and during feeding on most farms. The inability to remove sufficient quantities of silage from silos between feedings or poorly packed silage are two difficulties producers must overcome. Feeds that undergo aerobic deterioration have reduced nutritional value and present challenges and waste, such as disposal of spoiled feed. Milk yield of cows fed aerobically unstable corn silage declined approximately 7 lbs during 14-day feeding periods.4 Improving the aerobic stability of silages could confer a substantial advantage to producers.

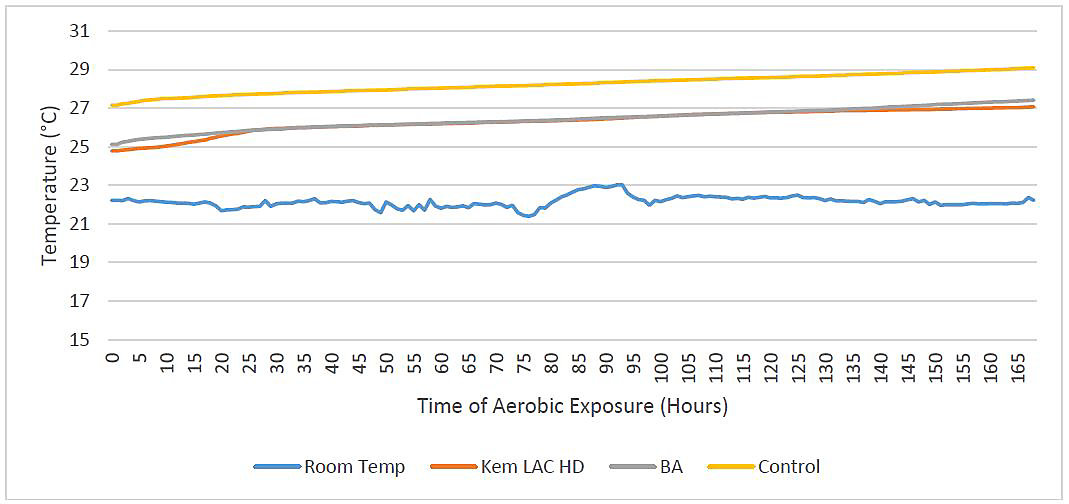

Another trial evaluated the effectiveness of Kem LAC HD (KL) and Product BA on the aerobic stability of alfalfa silage. Second-cutting alfalfa was treated with Kem LAC HD, BA or water as the negative control (NC). The objectives of this inoculant evaluation were to assess the effects of Kem LAC HD versus BA versus epiphytic bacteria on fermentation, dry matter recovery, aerobic stability and feeding value of alfalfa silage.

Figure 2. Temperature of plant material over time during aerobic exposure of alfalfa ensiled for 75 days

The data collected during this trial show Kem LAC HD and BA prevented alfalfa silage from heating for a significantly longer (P = 0.043) period of time compared to NC silage. Both inoculants would impart greater stability to the silage in order to help producers manage feeding strategies. For livestock producers, silage stability at feed-out, during TMR mixing and in the feed bunk, promotes improved intakes and performance.

References

1Kemin Internal Document, 16-00024.

2Kemin Internal Document, 11-00000.

3Kemin Internal Document, 12-00015.

4Kemin Internal Document, 12-00008.

Contact Kemin Animal Nutrition & Health - India

- California Supply Chain Act

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

- Change Cookie Consent

- Animal Welfare Statement

© Kemin Industries, Inc. and its group of companies all rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements