You are viewing South Asia

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

- Global

Choose Your Location:

- United States

- Canada

- Mexico

Popular Searches

- Animal Nutrition & Health

- CholiPEARL™

CholiPEARL™

Required By The Ruminant

It has been observed in several studies that a post-ruminal supplementation of choline improves milk production and helps the liver function. Increasing the intestinal supply of choline improves milk production in lactating dairy cows approximately 7% over controls, making it a crucial consideration for dairy farmers in South Asia.

Pathway To Prevention

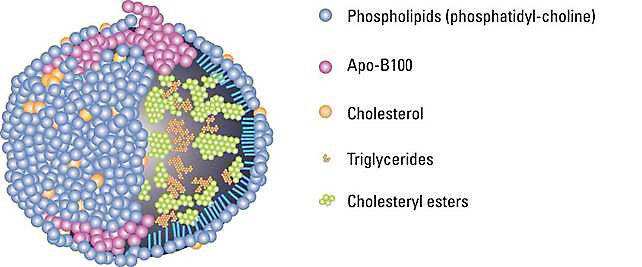

One of the primary roles of choline is the synthesis of phosphatidylcholine, an essential component of cell membranes. In addition, this phosphatidylcholine is required for the synthesis and secretion of molecules known as very low density lipoproteins (VLDL) in the liver. VLDL are important molecules necessary to avoid fat accumulation in the liver. Therefore choline status is a key factor in alleviating the severity and incidence of fatty liver and may have some application in the transition dairy cow.

Transition Period Nutrition

When should rumen-protected choline be fed?

During the transition period, dairy cows are under stress due to the negative energy balance. As a result, body fats are mobilized to supply enough energy to the body. The body fats need to be transformed into VLDL in the liver in order to be used as an energy source by the different body tissues.

Due to the role of choline in VLDL secretion (see previous question) the recommended period for rumen-protected choline application is during the transition period, 3 weeks before and up to 3 months after calving.

CholiPEARL is recommended before and after calving at a rate of 50-100 g/cow/day respectively.

Unique Protection

Are all rumen-protected sources of choline the same?

The most commonly used choline products in ruminant diets are unprotected forms. Non-protected choline is degraded in the rumen up to 98% (Sharma and Erdman, 1989.). This approach only adds cost to the supplement due to the high rumen-degradation rate of unprotected choline.

Most of the rumen-protected choline sources use a fat coating protection. The key differentiation point among the products is the technology used in the process. The most common technique is spray cooling. This technology relies on ambient temperatures to cool down the fat during the spraying process. This adds a lot of variability to the final product and inconsistent results can be expected.

Only CholiPEARL uses the spray freezing technology with unique handling and releasing characteristics. Thanks to this technology, each step of the production process is controlled allowing us to optimize the production, delivering a rumen-protected product with optimum rumen protection and high bioavailability.

How Do I Work With CholiPEARL?

- Storage/Handling

- Keep the product stored in a cool and dry place in the original package. Once opened, close bags tightly and store in a dry place

- Use in total mixed rations (TMRs) or as a top dress. Add to TMRs with other minerals and supplements. Feed out within four weeks

- Mixing

- This is a uniform product that mixes well and does not stratify. It can be mixed in grain and protein supplements with 10-12% moisture for a maximum of a three-minute mixing time

- Pelleting

- The product is pellet stable at temperatures between at least 70-80°C

- Feed Stability

- CholiPEARL is stable in complex mix (silage and concentrates) for at least 7 days

Contact Kemin Animal Nutrition & Health - India

- California Supply Chain Act

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

- Change Cookie Consent

- Animal Welfare Statement

© Kemin Industries, Inc. and its group of companies all rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements