Mold Inhibitor

Feed CURB™ and Kemin are recognized as one of the pioneers in feed preservation. Feed CURB™ Dry, a free-form propionic acid for feed, helps to preserve the nutrient value and quality of feed by inhibiting mold contamination.

Feed CURB™ has changed how feed and feed ingredients are handled and stored. By controlling spoilage organisms, Feed CURB™ gives the producers of meat, milk, and eggs, a powerful management tool to optimize production by wasting less feed and maintaining quality in their operations. They can also reduce the risk of mycotoxin contamination in the feed and feed ingredients.

MOLD INHIBITOR RECOGNIZED WORLDWIDE

Feed CURB™ is a mold inhibitor based on propionic acid for livestock feed, formulated to inhibit mold growth, prolong the shelf-life of bagged feed, processed feed ingredients, and total mixed rations (TMR). Feed CURB™ coats the feed and feed ingredients to deliver reliable protection against a range of mold species, it protects animals and poultry production.

Feed CURB™ Dry is developed for feed manufacturers and livestock and poultry producers who choose not to handle liquid products. The technology that is used by Kemin to manufacture Feed CURB™ Dry results in a free-flowing, granular product with excellent mold control efficacy. Feed CURB™ Dry can be applied in base mixes and premixes, through micro bins, or as a hand-added ingredient.

SELECTING THE RIGHT MOLD INHIBITOR

It is critical to know that each organic acid has a different effect in controlling molds when choosing a mold inhibitor

The use of free acid is a better mold inhibitor compared to the salt form (Paster)1. Free acid has a contact killing effect while the salt form requires a high moisture level to enter the mold cell and kill the mold.

EFFICACY OF FEED CURB™ IN FINISHED FEED

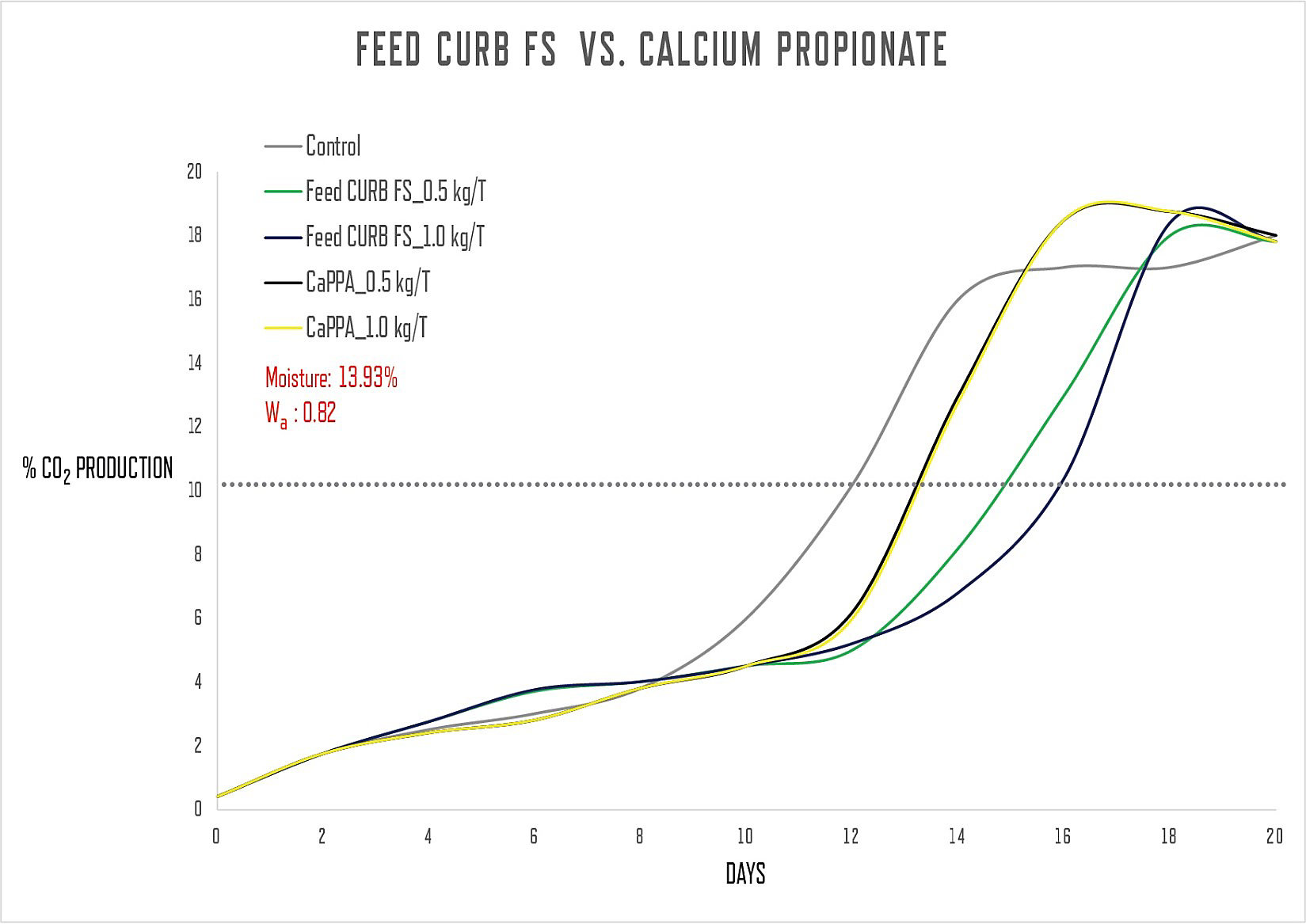

In Figure 1, a study comparing Feed CURB™ Dry mold inhibitor and calcium propionate in the finisher feed shows that the increased application rate of calcium propionate did not change the ability to control mold spoilage. Whereas, increasing the application rate of Feed CURB™ Dry from 0.5 kg/T to 1.0 kg/T has further improved its efficacy and significantly reduced mold growth in the finisher feed during the 3 weeks of monitoring.