Improving Milling Efficiency

How to Ensure Feed Processing Productivity & Profitability

Feed mills are fundamental to modern animal production and food security. The better modern feed mills are able to function the higher the quality of feed production animals will be able to consume leading to optimal growth potential and more wholesome food of animal origin for human consumption.

Compound feed production is a complicated operation that requires processing of a heterogeneous mixture of many ingredients into uniform pellets. Feed mills are faced with important challenges, such as ensuring profitability and safety of milling operations. Wide variations in the price and often the supply and quality of feed raw materials is also a significant challenge. Feed ingredients also typically have a high dusting potential, which not only results in material losses but also consequently financial losses.

Other areas of feed milling improvement that will pay dividends are sustainability and process control automation, to reduce variability and improve data collection and record-keeping.

Increasing Profitability Through Feed Processing Key Performance Indicators

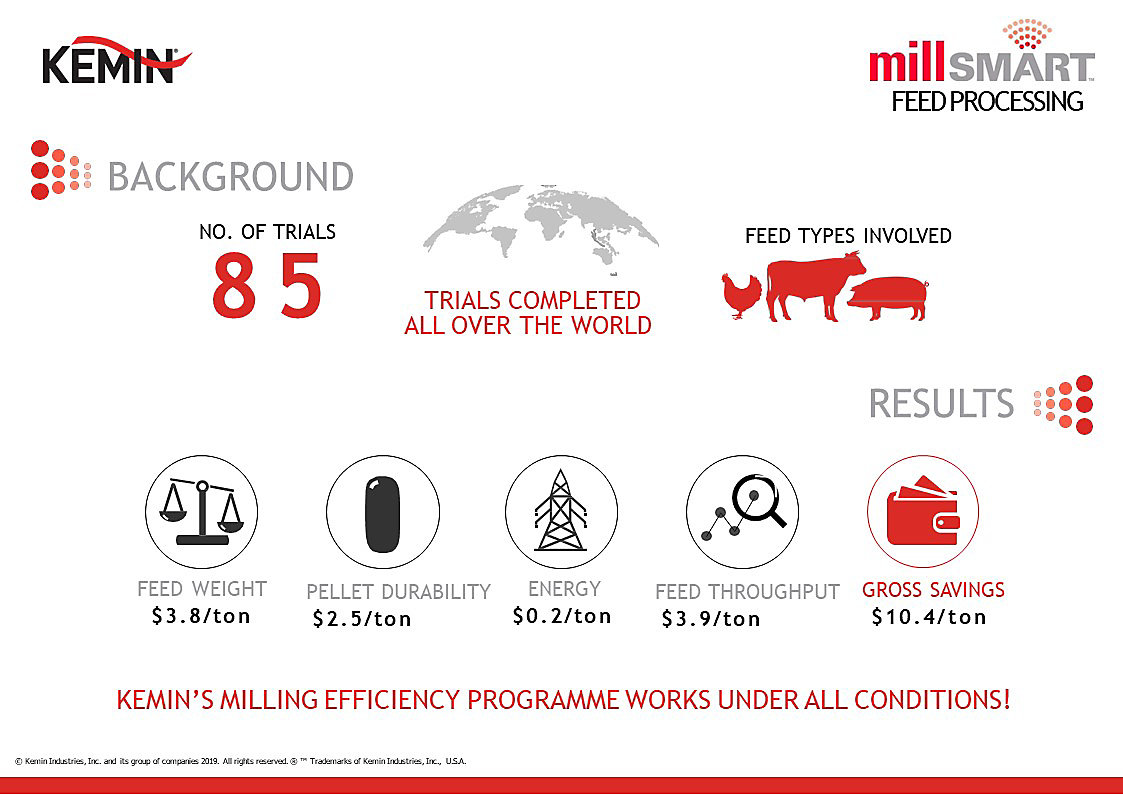

At Kemin, we are passionate about improving the health of production animals so as to encourage economic growth for farmers across the globe. In order to achieve our goal we have to look at the entire food chain holistically and improve every aspect thereof.

When it comes to feed processing, we help feed mills find additional ways to increase profitability by focussing on their Feed Processing Key Performance Indicators. We first need to assist in optimising the entire manufacturing process in order to maintain feed profitability.