Know Your Mycotoxins: T-2 and DON

Know Your Mycotoxins: T-2 and DON

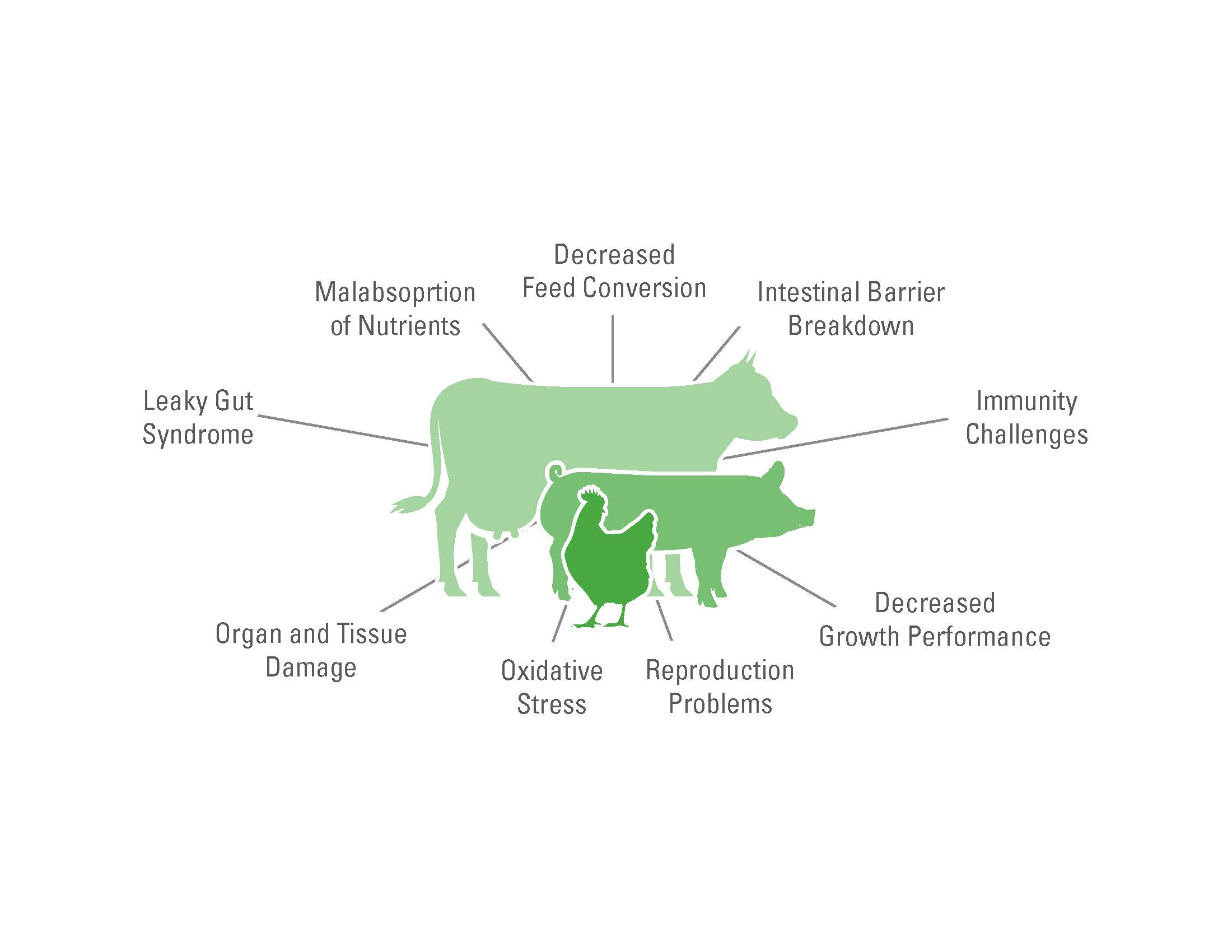

Environmental stressors like extreme heat and management factors such as movement to new barns or housing units can cause a breakdown in an animal’s natural defenses. That’s when mycotoxins like trichothecenes (T-2 and deoxynivalenol (DON)) can infiltrate internal systems and cause sometimes severe — even fatal — damage when left unchecked.