Protective Barrier Technology by Nature

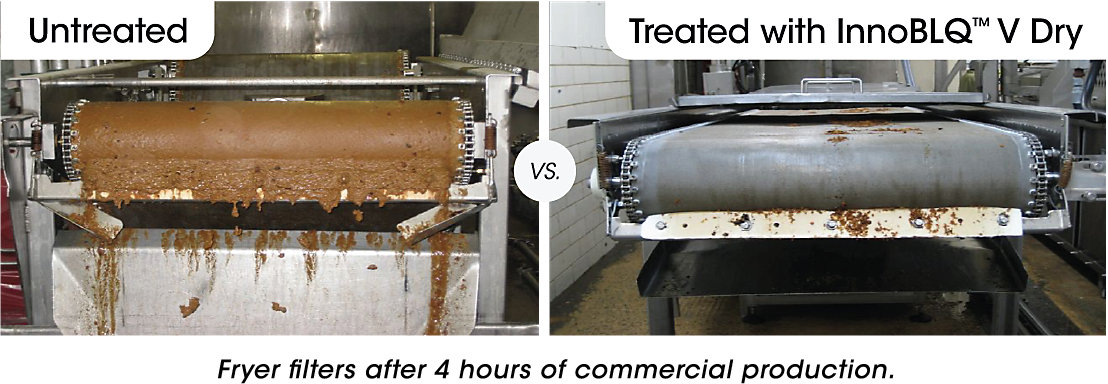

Kemin scientists even went a step further creating a protective barrier technology for the fried food during frying. Introducing InnoBLQ™ V Dry, Kemin’s fat-block technology made from a blend of plant-based proteins - specifically engineered to improve the quality of fried food while protecting the manufacturer’s bottom line by reducing operational costs, increasing yield, and meeting clean label demands. Highly versatile - InnoBLQ V Dry is applicable to a wide range of fried food products, including meat, seafood, vegetables, and various plant-based options. The product can be applied topically by dipping and spraying or added into the batter directly.

What makes InnoBLQ V Dry so effective?

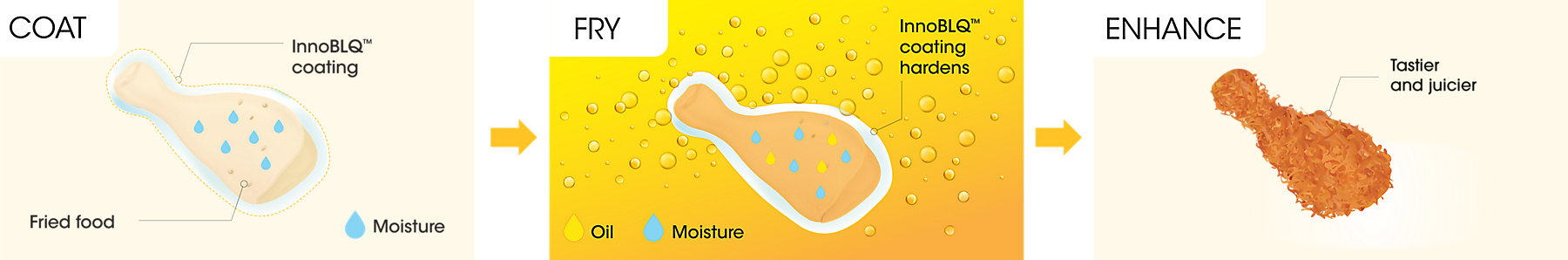

The secret lies in its modified protein technology. When food is fried in oil, the natural moisture content evaporates rapidly while oil is absorbed into the food during the process. The end-product is a crispy food that is in fact dehydrated, but greasier with added calories.

However, when treated with InnoBLQ V Dry, a micro barrier is formed around the product and functions as a protective layer during the frying process. This layer maximizes moisture retention, reduces oil absorption, and increases breading adhesion - all of which directly contribute to improved product yield in terms of quantity and quality.