Instructions for Use

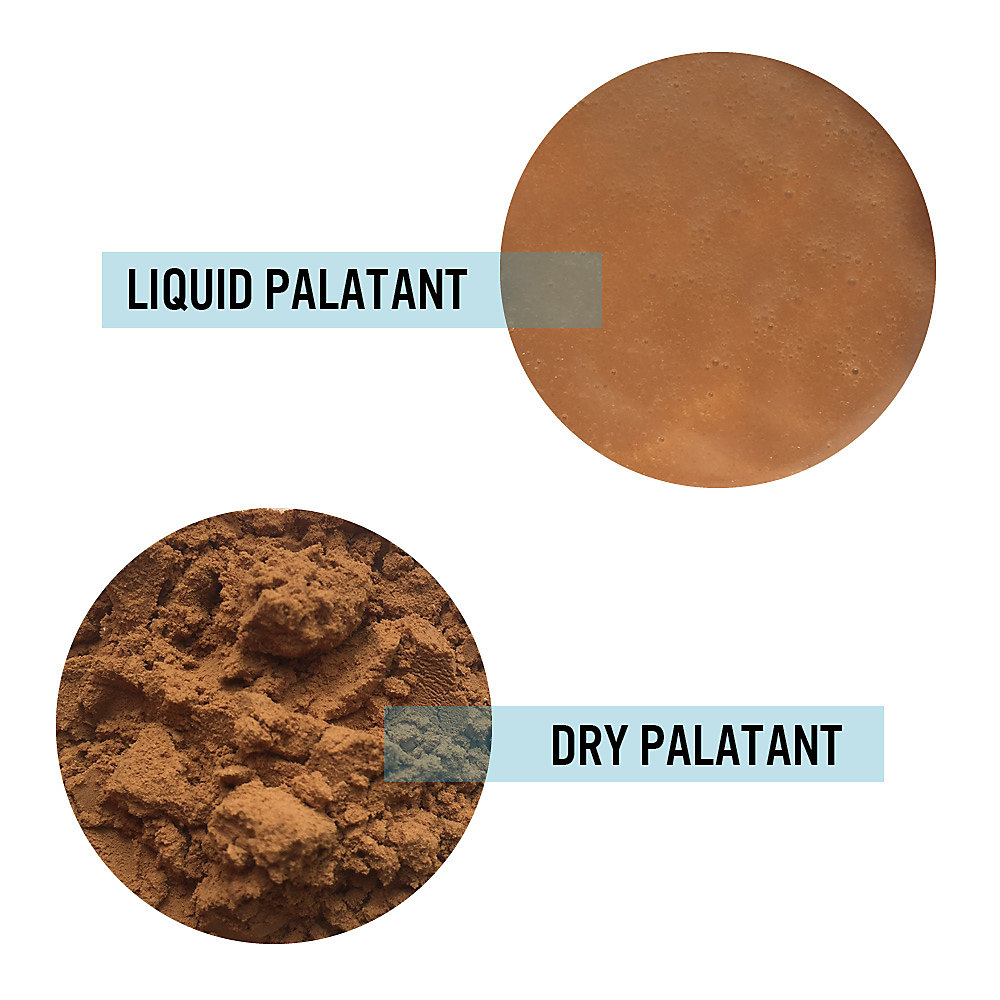

PALASURANCE and PALTEVA liquid palatants are recommended for topical application onto dry pet foods at 2% to 4% levels following an application of topical fat. For best results, apply evenly at ambient temperatures between 20-30°C.

PALASURANCE dry palatants are recommended for topical application onto dry pet foods at 0.5% to 2.5% levels following an application of topical fat. For best results, apply evenly at ambient temperatures.

Kemin also offers a line of concentrated dry palatants, granulated dry palatants, dry hydrolysates and dry protein sources which are designed for use in treats, supplements and wet pet foods.

Storage

For best results, do not store PALASURANCE or PALTEVA palatants at freezing temperatures or near direct heat. Store in a dry, cool and clean environment in the original, sealed container or, for liquid palatants, a recirculating/mildly agitated bulk tank. Temperature changes can cause clumping, and in some cases, alter the flavor of dry palatants.

It is recommended that bulk storage tanks and dry application equipment be cleaned and sanitized at least once per year at a minimum.

Kemin's Technical Service Managers and Account Managers are available to address your specific requests or questions regarding handling, application, usage or storage.