Today, Kemin’s application systems apply our products in the production process of feed mills, crushing facilities, rendering facilities, pet food facilities and more. To help offer new digital technologies to the animal nutrition professionals who use our systems, we have created KEMINCONNECT.

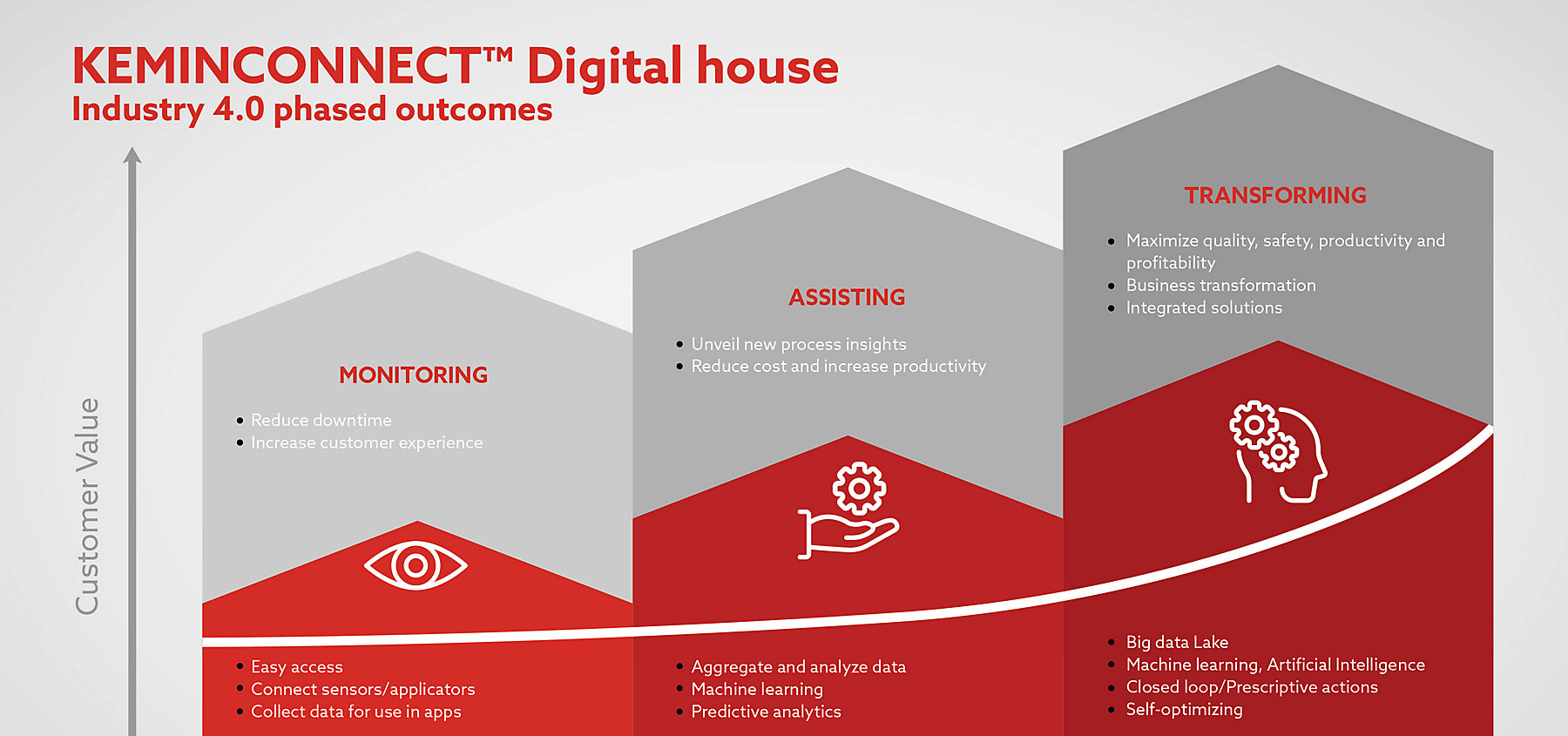

KEMINCONNECT is our newest digital application management platform that provides customers with analytical insights to make data-driven decisions that optimize processes and operations. Created by Kemin specifically for our customers, KEMINCONNECT is tailormade to integrate our application system into customers’ existing production processes.

With KEMINCONNECT, we are confident that customers will enjoy increased agility and reactivity from our support teams, and operators will gain additional insights on how to improve their processes and application systems.