by Vidya, A., Harikumar, S., Satish K., and M. Rajalekshmi

Improving the efficiency of feed utilization is essential as feed accounts for the largest cost in fish farming. However, certain nutrient rich ingredients in the feed cannot be fully digested and metabolized by the animal resulting in partial or incomplete absorption of such nutrients, which results in a negative impact in the overall performance and growth of the animals. Application of specific enzymes in fish feed can help in eliminating the effects of anti-nutritional factors and improve the utilization of dietary energy and amino acids, resulting in enhanced performance of fish, shares Ms. Vidya, Regional Technical Manager for Kemin AquaScience.

INTRODUCTION

According to a report by Food and Agriculture organization (FAO), global population is expected to grow and reach 9 billion by 2050 and one critical challenge of growing population is the supply of food and protein source. Fishes are known to be one of the most energy efficient protein sources with average food conversion ratio (FCR) ranging from 1.2 to 2.0, having high protein (18 to 20g per 100g of serving) and low calorific value (96 to 208 calories per 100g of serving). For a growing population, it is important that feed given to farmed fish remains sustainable. Enzymes will help in using economical raw materials, increase performance, and decrease anti-nutritional factors.

RAW MATERIALS IN FISH FEED

Most of the raw materials used in fish feed industry are plant based; corn, corn gluten meal, rice bran, wheat bran, sunflower seed meal, groundnut meal, cottonseed meal, linseed meal, copra meal and DORB (de-oiled rice bran). All these raw materials have high fiber, which are the undigested part of the feed, not digested by the innate enzymes naturally found in the fish gut. The non-digestible fiber includes high levels of non-starch polysaccharides made of cellulose, hemicellulose and lignin. There are many evidences that have reported increase in the viscosity of digested feed due to the presence of non-starch polysaccharides, which leads to decrease in the available nutrients in the feed.

INNATE ENZYMES IN FISHES

The most common enzymes reported in carps are given in Table 1.

Table 1. Limited number of digestive enzymes reported in carps

Lipase |

Amylase |

Trypsin |

Maltase |

Chymotrypsin |

Cellulase- exogenous (microbial) |

Most feed ingredients of plant origin also contain anti-nutritional factors such as protease inhibitors (Kunitz trypsin inhibitors, Bowman-Brik Inhibitors), lectins, saponins and phytic acids. Unlike other anti-nutritional factors, phytic acid is not degraded by heat treatment during pelleting. Phytic acid is known to interfere in absorption of minerals like calcium, magnesium and potassium; having an adverse effect on the growth and development of fishes.

EXOGENOUS ENZYME SUPPLEMENTATION

Supplementation of exogenous NSPases (non-starch polysaccharides degrading enzymes) and phytases is known to improve digestion of natural and supplemented feed, thereby improving the feed efficiency and performance.

Addition of NSPases and phytases is a smart solution for improving the profitability in aquaculture. It not only helps in the digestion of high fiber containing raw materials but also helps in reducing the usage of minerals like MCP and DCP (mono and dicalcium phosphate). Kemin AquaScience research team has formulated an enzyme product with the combination of NSPases and phytase based on the raw materials used in fish feed and the feeding behavior.

ZyvantaTM Aqua 100 DR is a multi-substrate enzyme powder containing NSP (Non-Starch Polysaccharide) enzymes and phytase developed to improve the nutrient quality of fish feed. Application of the product is at farm level, where it is mixed with the feed right before consumption by the animals.

This paper summarizes the application and benefits of ZyvantaTM Aqua 100 DR through digestibility and growth trials conducted at Kemin AquaScience Research Laboratory and subsequent commercial trials done in, India, and its application in liquid form ZyvantaTM Aqua 100 LQ developed to apply at feed mills using Post Pellet Liquid Application Technology (PPLA).

IN VITRO DIGESTIBILITY STUDIES

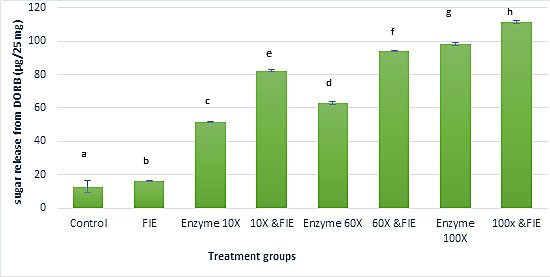

In vitro sugar release by ZyvantaTM Aqua 100 DR in combination with fish intestinal extract (FIE) was prepared by mincing the whole intestine extracted from Rohu fingerlings using phosphate buffer (7.4) in ice cold conditions. de-starched, de-oiled rice bran was studied at pH 7.4 and 37°C using Nelson-Somogyi method. Significant improvement in digestibility (p ≤0.05) was observed when the ZyvantaTM Aqua 100 DR was used alone and in combination with FIE (fish intestinal extract). Studies indicated a synergy between endogenous enzymes and supplemented enzymes (Fig.1).

Figure 1. Effect of ZyvantaTM Aqua DR (enzyme) without and with fish intestinal extract (FIE) on sugar release from DORB. Each experimental data represents the mean of the values ± standard error (n = 3), P<0.05

IN VIVO GROWTH STUDIES

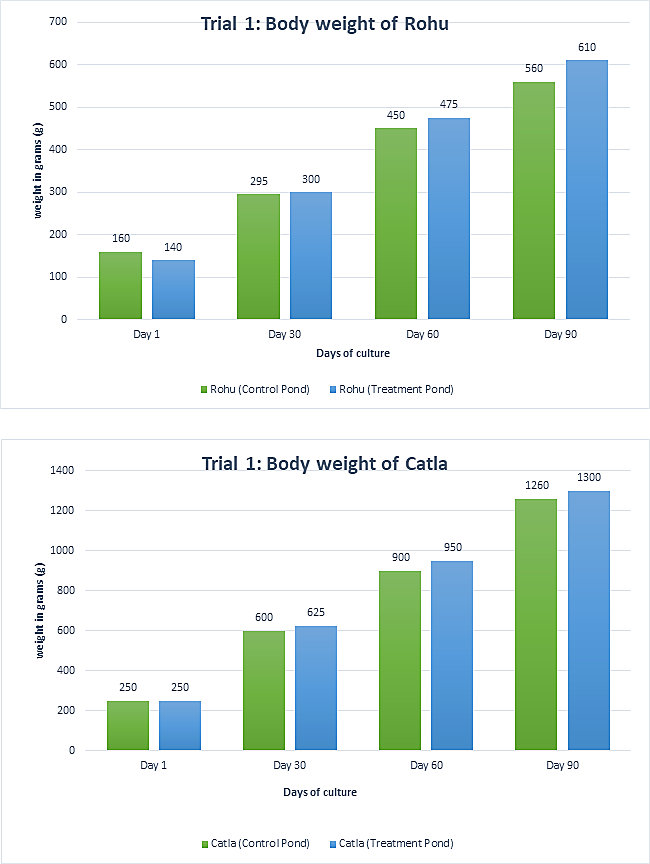

Two in vivo trials were conducted in commercial farms at Bhimavaram, Andhra Pradesh to demonstrate the benefits of Zyvanta Aqua 100 DR. The farms had a mixed culture of Indian major carps Rohu and Catla. Zyvanta Aqua 100 DR was coated on top of the feed with a gel binder prior to feeding, at a dosage of 1g/kg and control pond fishes were fed with feed without product supplementation. The fish were fed once in a day for a period of 90 days. The effect of enzyme supplementation on weight gain was recorded by netting approximately 100 fish, thrice from sides of the pond and the average weight was calculated and recorded once in 30 days.

Farm trial I

The details of the farm trial I is given in the table 2

Table 2. Farm trial I details

Trial I |

Control |

Treatment |

Area of culture |

15 acres |

10 acres |

Stocking density |

Rohu- 25,000 & Catla- 2000 |

Rohu- 35,000 & Catla- 3000 |

Diet |

Commercial fish feed without supplementation of enzymes |

Control feed + ZyvantaTM Aqua 100 DR @ 1g/kg |

Results

Commercial trial I showed increase in weight gain in treated group than control groups (Fig. 2). At the end of the trial, the treatment group having Rohu weighed 50g more and Catla weighed 40g more than the control group.

Figure 2. Body weight increase in trial I (Rohu and Catla).

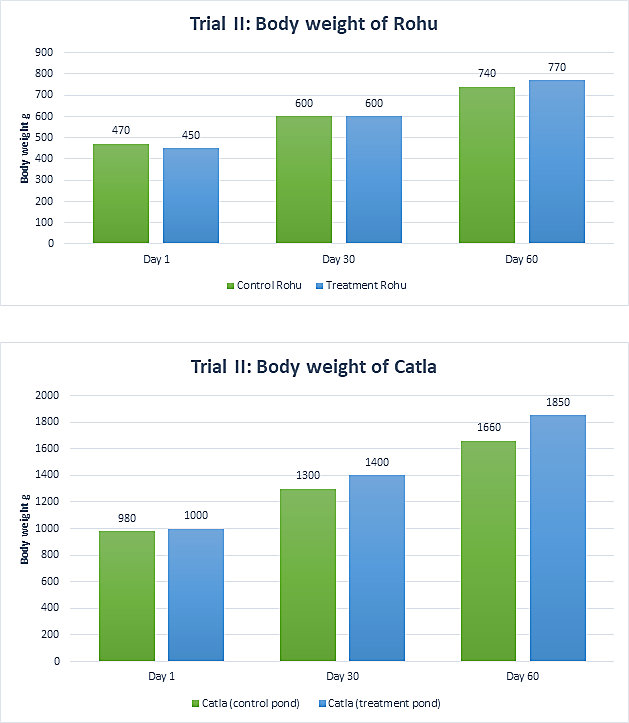

Farm trial II

The details of the farm trial II are given in the table 3.

Table 3. Farm trial II details

Trial II |

Control |

Treatment |

Area of culture |

10 acres |

8 acres |

Stocking density |

Rohu- 21,000 & Catla- 2000 |

Rohu- 17,000 & Catla- 3000 |

Diet |

Commercial fish feed without supplementation of enzymes |

Control feed + ZyvantaTM Aqua 100 DR @ 1g/kg |

Results

Trial II, control group of Catla were 20 grams less than the treatment group, and the same group gained 190 grams more than control group at the end of the trial (Fig. 3). similarly, Rohu in treatment ponds gained 30 grams more than the control group at the end of the trial.

Figure 3. Body weight increase in trial II (Rohu and Catla)

Skin Pigmentation

In both the above trials better utilization of phytoplankton and algae resulted in enhanced carotenoid bioavailability. Supplementation of Zyvanta Aqua 100 DR showed an increase the pigmentation of carps. This was observed by visual examination during the trials and was consistently reported by farmers.

APPLICATION OF LIQUID ENZYMES IN FISH FEED MILLS USING POST PELLET LIQUID APPLICATION (PPLA)

Need for liquid enzymes in fish feed

Inclusion of additives in the feed can be done in two ways; in-process addition and postprocess addition. The temperature of the feed during extrusion usually rises to the range of 110 to 120°C. Application of heat sensitive supplements such as enzymes and probiotics is not possible through in-process technique. Application in the form of liquid additives after pelleting is a good alternative. It is a common practice in feed mills to coat the feed pellets with oil after extrusion. The level of oil used is often as high as 1 to 3%, making the coating process easier. On the other hand, enzymes are required in much lesser quantities (0.1 %), which necessitates the need for high accuracy and precision in the coating process.

POST PELLET LIQUID APPLICATION (PPLA) TECHNOLOGY

The most critical factor in post pelleting application is the precision of the dose given and co-efficient of variance (CV) of the additive in feed sample; the maximum CV percentage in daily ration portion of target animal diet is 10%. It is also vital that the enzyme coated on the feed must have good binding with the feed matrix to prevent the leaching of enzymes into water.

We at Kemin AquaScience have developed a tailor-made liquid application system called SMART BOX – PPLA System. The equipment sprays liquid enzyme on the surface of the finished pelleted feed right before the bagging step. The system contains PLC (Programmable logic controller) for automation, gravimetric batch controller, feedback sensor, precision dosing pumps, air atomized spray nozzles, high pressure dosing pumps, impact weigher and spray chamber.

The unit also consists of weighing tank, rotary feeder, baffle type dispenser, carrying conveyor and spray nozzles. The three-baffle design ensures uniform spraying of the product on the entire pellet. For accurate dosing of the enzyme, measurement of feed flowing into the spray chamber is critical. The six air atomized spray nozzles in the SMART BOX – PPLA System ensures that the feed is evenly distributed with liquid enzymes.

CONCLUSION

Post pellet application of enzymes application for fish feed is an attractive way of solving the indigestibility of high fiber containing feed raw materials. Not only does it improve the fish performance, but also decreases the eutrophication of pond water caused due to release of undigested feed and phosphorus, thus helping the farmers in maintaining water quality and animal health.

For Media and Enquiries contact: Vinoth Kumar R (vinothkumar.r@kemin.com) is Global Communications Manager for Kemin AquaScience™, based in Chennai, India.