Introduction

Despite the trend towards low-fat food, fried products remain popular. On the other hand, consumers are better educated and want healthy and environmentally friendly ingredients. Retailers are therefore looking at their suppliers to make sure they can meet the requirements of their customers.

Generally, liquid oils are more sensitive to oxidation and therefore they used to be hydrogenated to enhance stability for the catering industry and fastfood sectors. However, considerable amounts of trans fatty acids are formed during hydrogenation, which are undesirable from a nutritional and health perspective. Since also consumers are well-informed about the health risks of trans fats, there is a clear trend to look for alternatives to protect frying oils from oxidation.

Deep frying process

Deep frying has been known since ancient history and brings about an attractive change of flavour, texture and colour in the food. However, deep frying also leads to undesired chemical and physical changes that affect both the quality of the deep frying medium and the fried food.

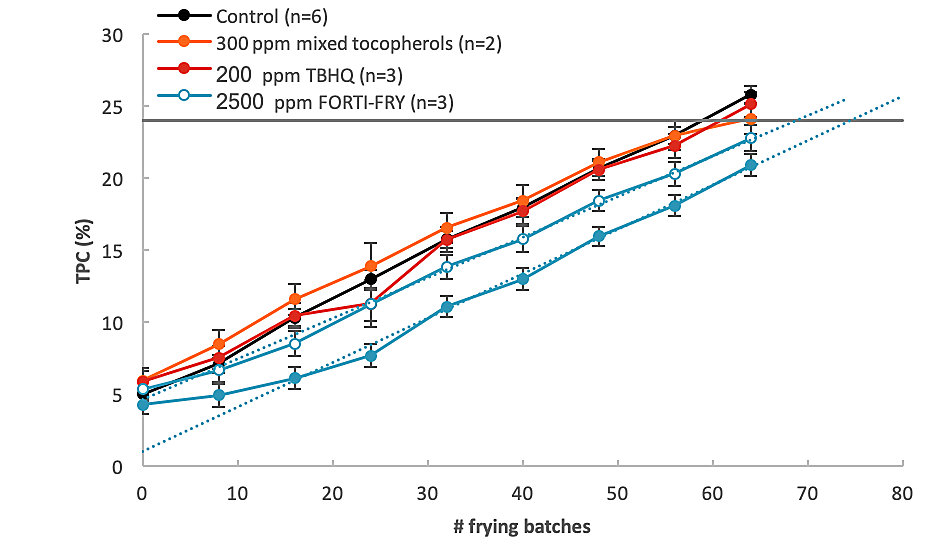

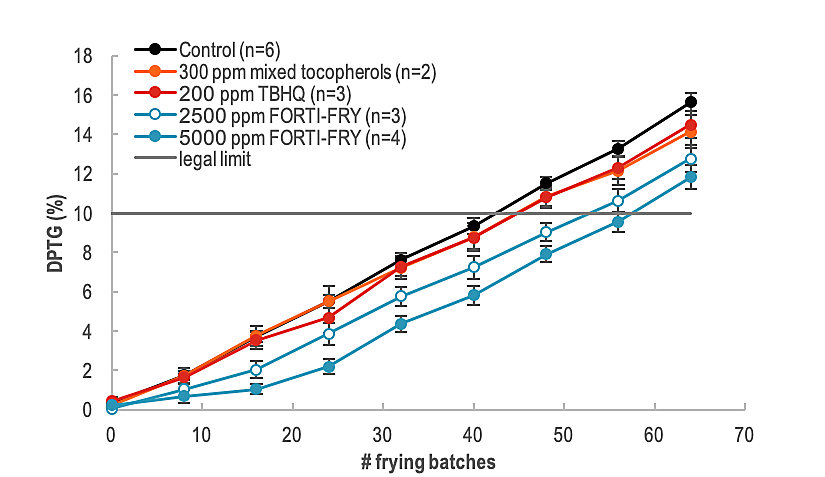

Frying is a complicated, multi-factor process where the frying oil undergoes a complex series of oxidation reactions. This complexity increases further when food is introduced into the hot oil. In fact, fats and oils are mixtures of triglycerides. These nonpolar components can be strongly affected by oxygen, heat and water. Total polar compounds (TPC) are the major decomposition products of triglycerides present in frying oil. Various chemical reactions including oxidation, hydrolysis and polymerisation result in the formation of polar compounds such as free fatty acids, aldehydes, mono-and diglycerides and polymerised triglycerides.

Darkening of frying oil

The colour of frying oil will become more intensive and darker and is highly affected by the type of food being fried. Darkening of the oil is caused by Maillard reaction products of amino acids and unsaturated carbonyl compounds. This reaction results in the formation of a variety of heterocyclic compounds which contribute to the flavour of the fried food.

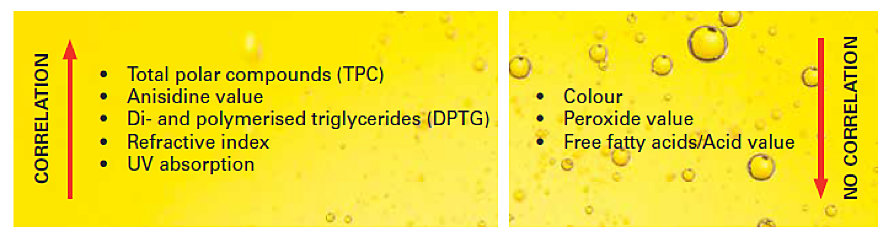

However there is no direct correlation with the colour change and the deterioration of fat. Oil can turn dark quickly, while still having a good oxidative status. On the other hand, chemical parameters such as polar compounds and anisidine value will increase when frying oil becomes rancid.

Figure 1: Correlation of different parameters with oxidative deterioration of the oil