You are viewing EMENA

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

A global presence, with local expertise. Visit our regional sites:

- United States

- Canada

- Mexico

Popular Searches

Ingredients for a Sustainable Future.

To help protect the health and safety of people, pets, animals, plants, and the planet, Kemin is dedicated to sustainably transforming 80% of the world’s population.

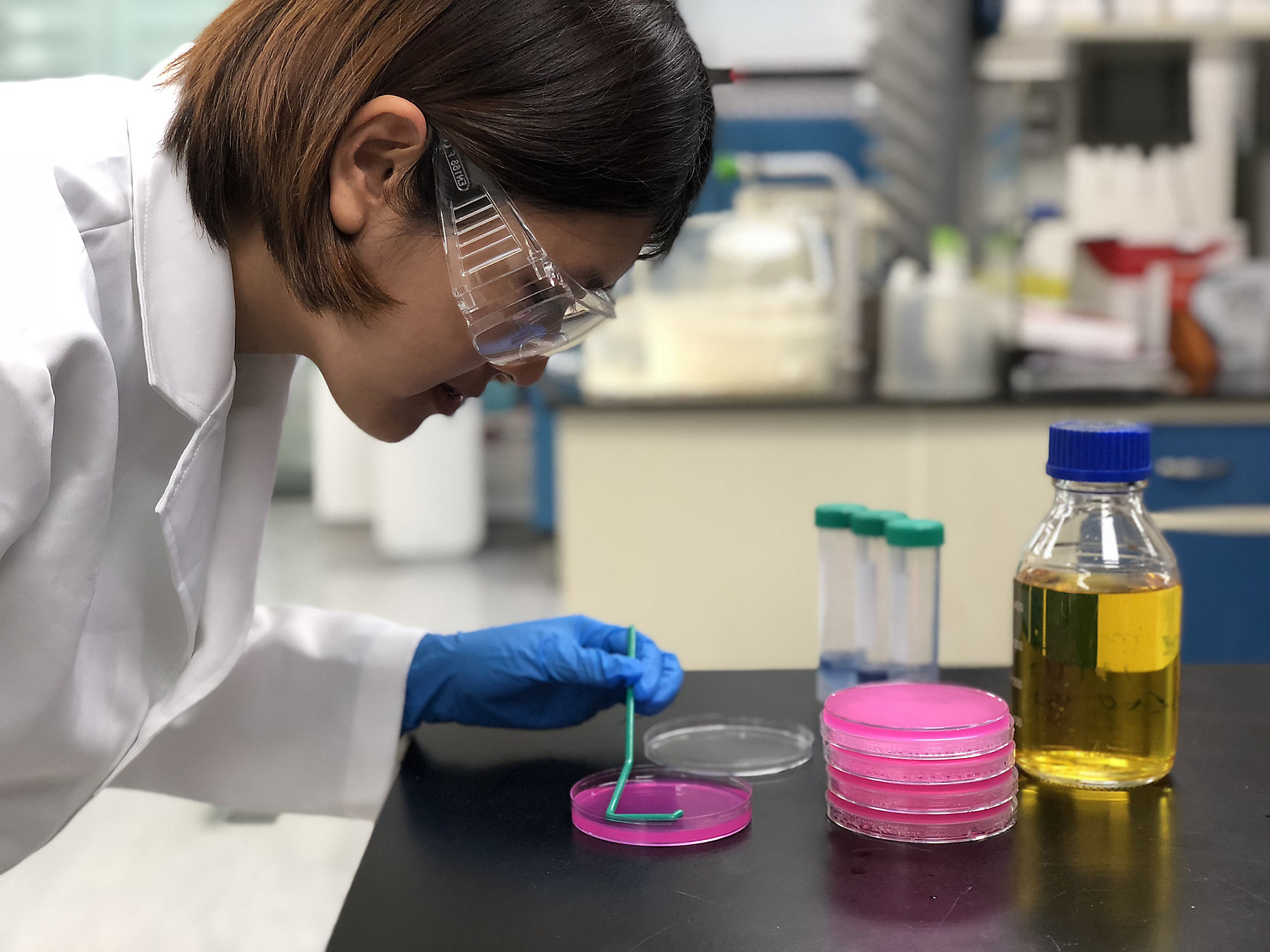

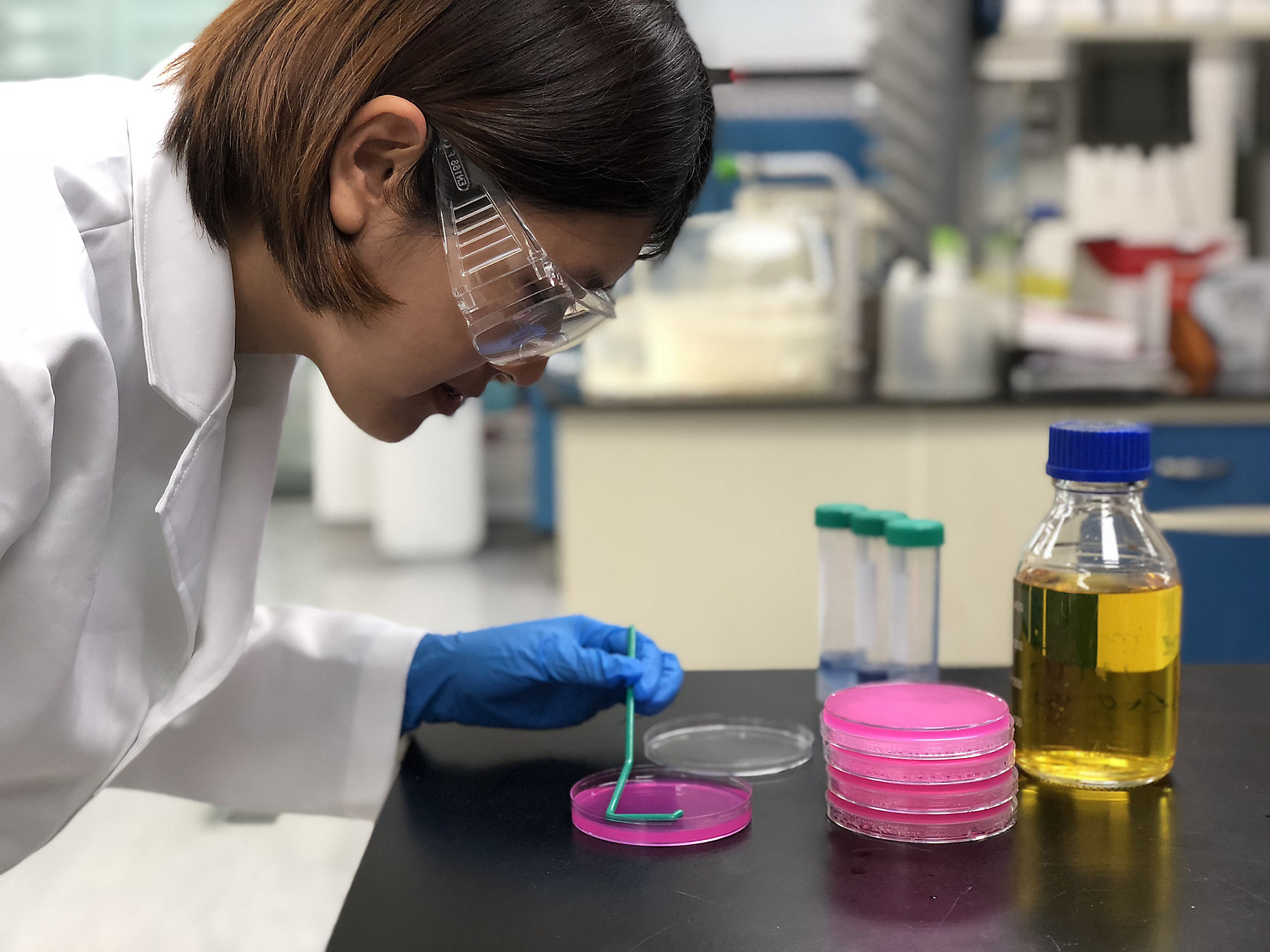

Based in Science. Rooted in Service.

Through innovative laboratory services and profound analyses, our scientific support is at the heart of what we do.

Inspired Science That Transforms.

As a biotechnology company committed to innovation, we use science to unlock solutions to the world’s challenges.

Sustainability

Service

Innovation

Compelled by Curiosity

Plant Science

Social Responsibility

We are compelled to meet the global demand for safe animal protein. From novel feed ingredients to essential nutrients, our innovations help producers raise healthy livestock and poultry today, and build a resilient foundation for the future.

Animal Nutrition & Health

We are compelled to provide everyone the opportunity to live a healthier life. We turn our curiosity towards new ways to continuously enhance the health and wellness of people worldwide with cutting-edge, science-backed ingredients to support vision, immunity, cognition, and more.

Human Nutrition & Health

We are compelled to provide safe and delicious ingredients to improve our pets’ food so they can have the best quality of life. From oxidation control and food safety to palatability and nutrition, Kemin is compelled by curiosity to assure pets are living a happy and healthy life around the world.

Pet Food & Rendering Technologies

We are compelled to help keep our food fresher and safer for longer. Across the entire global food supply chain, from meat and poultry to baked goods, our ingredients provide food manufacturers with the ability to produce safe and high-quality food products to ensure that people have the highest quality food products—for themselves and for families around the world.

Food Technologies

We are compelled to meet the growing demand for safe animal proteins from fish and shrimp. Our dedicated aquaculture experts and team of scientists are sharing and implementing innovative solutions to improve quality and product efficacy within the industry.

Aquaculture

We are compelled to ensure that everyone has access to both healthy plants and a secure food supply. We address the difficulties of diverse growing conditions and ever-changing environmental factors by focusing our curiosity on new frontiers that will help growers yield robust plants and wholesome food.

Crop Technologies

We are compelled to pioneer sustainable, safe, high-quality garment finishing solutions. Because what we wear affects our planet, we are assisting with safe, quality clothing to reduce our carbon footprint. By advancing our formulas, we produce garments that are better performing—for consumers and the planet.

Textile Auxiliaries

We are compelled to empower immune resilience that enables animals to better perform and stay healthy so producers can continue feeding the world. With a strong awareness of global trends for food and animal production, Kemin has a clear perspective on how to deliver trusted vaccine technologies.

Biologics

At Kemin, we are compelled by curiosity.

It is the driving force that pushes us toward our vision of transforming lives. With science as our foundation and an inextinguishable spirit of discovery, we strive to improve life for people, pets, plants and animals. We embrace opportunities that allow us to explore creative solutions for the world’s complex challenges. We look beyond what is—to see what could be.

Kemin has more than 15 manufacturing facilities worldwide.

90

Kemin operates in more than 90 countries.

120

Kemin customers are in more than 120 countries.

500+

Kemin offers more than 500 specialty ingredients to customers worldwide.

Connect With Us

We would love to hear from you. Let us know how we can help.

Products

Careers

Careers

- California Supply Chain Act

- Email Disclaimer

- GDPR Personal Data Addendum

- General Terms & Conditions for Vendors

- Global Environmental Policy Statement

- Indirect Cost Estimates

- Kemin Terms & Conditions

- Modern Slavery Act Transparency Statement

- Privacy Policy

- Sitemap

© Kemin Industries, Inc. and its group of companies all rights reserved. ® ™ Trademarks of Kemin Industries, Inc., USA

Certain statements may not be applicable in all geographical regions. Product labeling and associated claims may differ based upon government requirements.

You are viewing EMENA

- United States

- Canada

- Mexico

- South America

- EMENA

- Sub-Saharan Africa

- Russia

- South Asia

- Asia Pacific

- China

A global presence, with local expertise. Visit our regional sites:

- United States

- Canada

- Mexico

Privacy Policy

By browsing this site you permit us and our partners to place identification cookies on your browser and agree to our use of cookies for marketing. Review our cookies policy for details.